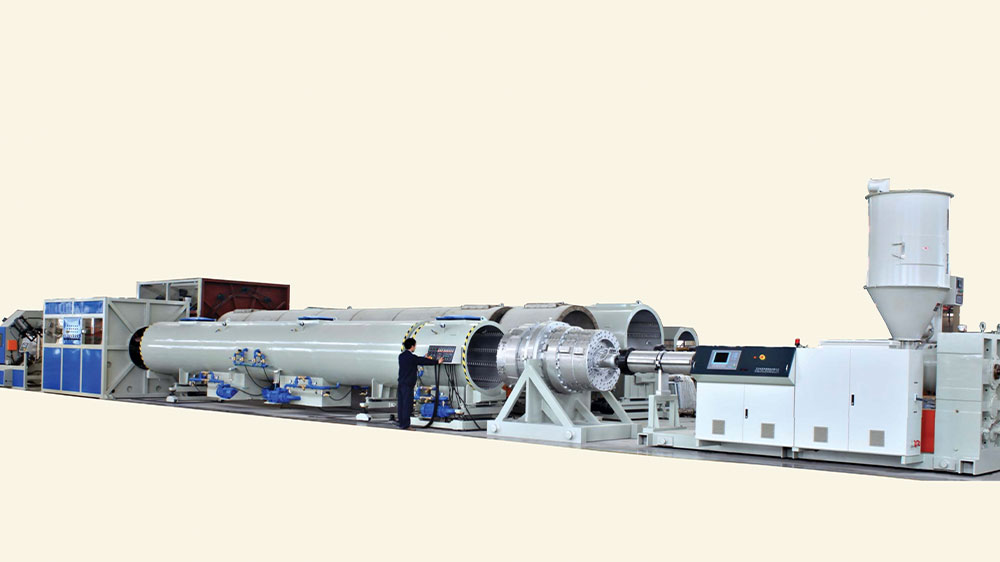

PE PP PC pombi chubhu extrusion muchina

Products Description

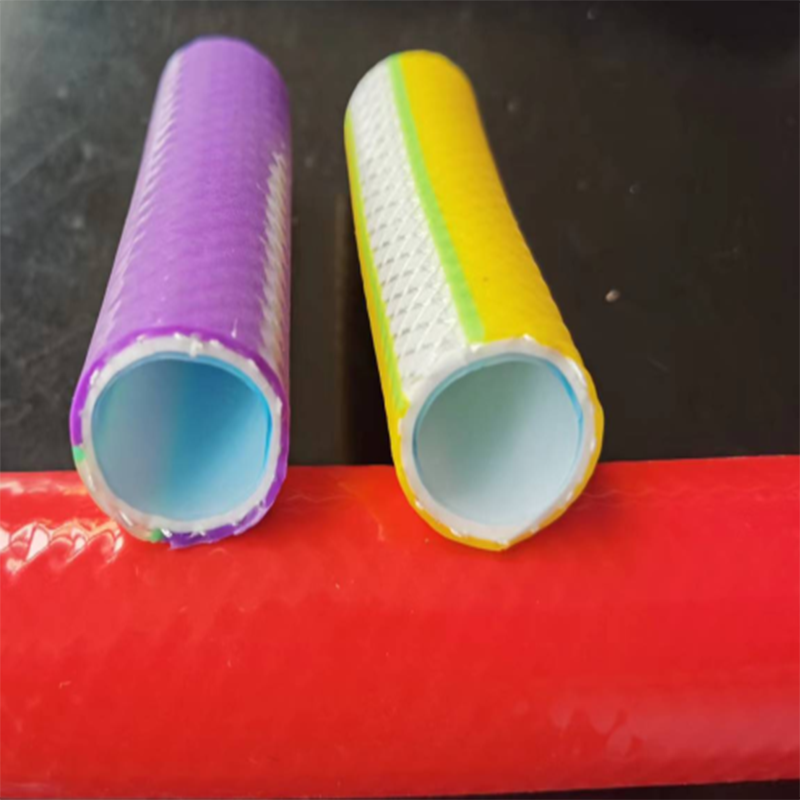

>> PE Pipe Extrusion Machine inonyanya kushandiswa kugadzira pombi dzekudiridza dzekurima, pombi dzemvura, pombi dzegasi, pombi dzinopa mvura, pombi dzetambo dzemakombi nezvimwe.

>> Iyo pombi ine zvimwe zvakanakisa senge kudziyisa kusagadzikana, kuchembera, kusimba kwemagetsi, kushushikana kwemamiriro ekunze kutsemuka, kwakanaka kusingagone, nezvimwe. ruzha, Gravimetric dosing unit uye ultrasonic ukobvu chiratidzo chinogona kuunganidzwa zvinoenderana nezvinodiwa nemutengi kukwira chaiko kwepombi.

>> Turn key solution inogona kupihwa, senge laser printer crusher, shredder, water chiller, air compressor etc. kuti uwane yakakwirira-giredhi uye otomatiki chubhu kugadzirwa.

>> Mafambiro eMafambiro: Raw material+ Master Batches → Kusanganisa → Vacuum Feeder → Pulastiki Hopper Drier → Single screw extruder → Co-extruder yeruvara tambo & Multi Layers → Mold → Vacuum Calibration Tangi → Tspfapfaidza Tangi Yemvura Inotonhorera → Kubvisa → Hapana Guruva Cheka → Kaviri/Rimwechete disc Winding/ Stacker → Yekupedzisira Chigadzirwa Kuongorora &Kurongedza

1. Single Screw Extruder

Single-screw extruder inogona kugadzira akawanda marudzi ezvigadzirwa zvepurasitiki senge firimu, pombi, bhodhi, rukwa, bhandi uye granules.

2. PE pombi kufa musoro

>> Yakakodzera HDPE, LDPE, PERT, PP, PPB, PPH, PP-R, PS pombi kugadzirwa

>> Diamita kubva Ø16 kusvika Ø1600 mm

>> Yakanyanya kunyungudika homogenity

>> Yakaderera kudzvanywa kwakavakirwa kunyangwe nezvakakwira zvakabuda

>> Nyusa chiteshi chekugovera system

>> Yakashongedzerwa neseramic heaters

>> Pipe musoro inotakura kuti zvive nyore kufamba

>> Misoro yepombi yakagadzirwa zvinoenderana nezvinodiwa zvekushandisa.

>> Kugadziriswa kuri nyore kuvonga kune yakagadziridzwa uye yakasimbiswa yakagadzirwa kuvaka.

Mumakore achangopfuura, musika wepurasitiki pombi iri kukura zvishoma nezvishoma muChina.PE, PPR uye UPVC pombi inoita basa rakakosha.Imo kuvandudzwa kwePE pombi kunoshamisa.PE pombi ine huwandu hwakawanda hwekushandisa.pombi yemvura uye gasi imwe yemusika mukuru wekushandisa.

Isu tiri Kushandisa iyo yakazara inoyerera nzira yepakati yekutsigira chimiro uye inobvisika yekuwana michina

Iyo chiteshi dhizaini yakadzivirira nzvimbo yakafa uye kuchengetwa.

Iyo yakagadziridzwa dhizaini yemugero inoyerera inopa iyo yakasimba kukanganisa kupikisa.

Zviri nyore kuunganidza uye disassemble.

Vacuum calibration tank

>> Yakakodzera PE pombi kugadzirwa

>> Diamita kubva Ø16 kusvika Ø1600 mm

>> Kureba kusvika 12000mm

>> 304 simbi isina tsvina ine pendi yekunze

>> Special mvura yekupfapfaidza iri panzvimbo yakanakisa yekutonhodza pombi zvakanaka

>> Yakakosha uye nyore yakagadziridzwa pombi inotsigira imwe neimwe pombi dhayamita

>> Yakaiswa vacuum nemapombi emvura anogona kushanda pasina chero kugadzirisa kwenguva refu

>> Special kutonhora yekugezera inogona kugadzirwa chaiyo extrusion kugadzirwa

Bvisa muchina

>> Pipe kubva Ø16 kusvika Ø1600 mm

>> High kudhonza simba pasina kurasikirwa chimiro mapaipi

>> Yakashongedzerwa ne2, 3, 4, 6, 8,10 kana 12 makonye maererano nekushandiswa

>> Servo mota kutyaira yekupa yakagadzikana torque uye kumhanya

>>Motorized positioning yemakonye ezasi

>> Kushanda kuri nyore

>> Dziviriro yakavharwa zvachose kuitira kuchengetedza kwakanyanya

>> Chain conveyor ane yakakosha rabha pads pamaketani ayo asina chiratidzo papombi.

>> Kuwiriranisa neiyo extruder screw kumhanya inobvumira yakagadzikana kugadzirwa panguva yekuchinja kukurumidza kwekugadzira

Cutting system

>> Otomatiki kuwiriranisa pamwe extrusion kumhanya

>> Planetary yakashongedzerwa dhisiki uye milling cutter yekucheka uye kukwezva

>> Chip-yemahara yakashongedzerwa nedhisiki blade kuve nechokwadi chekucheka kwakadzikama pasina guruva

>> Bata screen control panel

> Mafambiro ese ane mota uye anodzorwa ne control panel

>> Kuvharira pombi nekushandisa universal clamping kuti ishande nyore

>> Type yekucheka unit inosarudzwa zvinoenderana nepombi

>> Zvishoma zvekuchengetedza zvinodiwa

>> Yakavharwa zvachose uye yakachengetedzwa muchina kuitira kuchengetedzwa kwakanyanya

Product Paramenters

| Diameter range(mm) | Extruder model | Max.Kugona (kg/h) | Max.kumhanya kwemutsara (m/min) | Extruder power (KW) |

| Ф20-63 | SJ65/33 | 220 | 12 | 55 |

| Ф20-63 | SJ60/38 | 460 | 30 | 110 |

| Ф20-63 Dual | SJ60/38 | 460 | 15 × 2 | 110 |

| Ф20-110 | SJ65/33 | 220 | 12 | 55 |

| Ф20-110 | SJ60/38 | 460 | 30 | 110 |

| Ф20-160 | SJ60/38 | 460 | 15 | 110 |

| Ф50-250 | SJ75/38 | 600 | 12 | 160 |

| Ф110-450 | SJ90/38 | 850 | 8 | 250 |

| Ф250-630 | SJ90/38 | 1,050 | 4 | 280 |

| Ф500-800 | SJ120/38 | 1,300 | 2 | 315 |

| Ф710-1200 | SJ120/38 | 1,450 | 1 | 355 |

| Ф1000-1600 | SJ90/38 SJ90/38 | 1,900 | 0.6 | 280 280 |